Frequently asked questions

- How do I access the graphical user interface and operate C-Gate?

The web interface offers various options for visualising data and managing C-Gate. This can be called up with all current web browsers with the associated address. If your browser is not compatible, you will be informed of this on the web interface and you will receive a recommendation.

- Where is C-Gate (Edge Gateway) located?

C-Gate is installed in the control cabinet in the lower part of the door. It is an IPC with a label on the front. This label shows the login data and network information. If you have a system with several control cabinets, you will find C-Gate in the control cabinet of the master.

- Is C-Gate (Edge Gateway) supplied with power?

Check that the LED in the power button, at the bottom left of C-Gate, is lit. If it is lit white, the C-Gate is powered and switched on. If the LED is red or not lit, try to start C-Gate by briefly pressing the power button. If the IPC does not start, check that the LED on the power supply unit connected to the IPC is lit. If this is not the case, the 230V/110V power supply may not be present. Check this and/or contact CLOOS support.

- What are the various C-Gate (Edge Gateway) connections for?

For C-Gate operation, only the power connection and the network connections are relevant. No functions are available via all other connections (RS-232, WIFI, HDMI, USB, ...).

- What must be done in case of service (failure of the Edge Gateway)?

-

- If possible, shut down the IPC via the web interface.

- Disconnect the IPC from the power supply by pulling the plug on the left side.

- Make a note of which cable goes to which port and then disconnect the two network cables.

- Disconnect the earthing from the IPC.

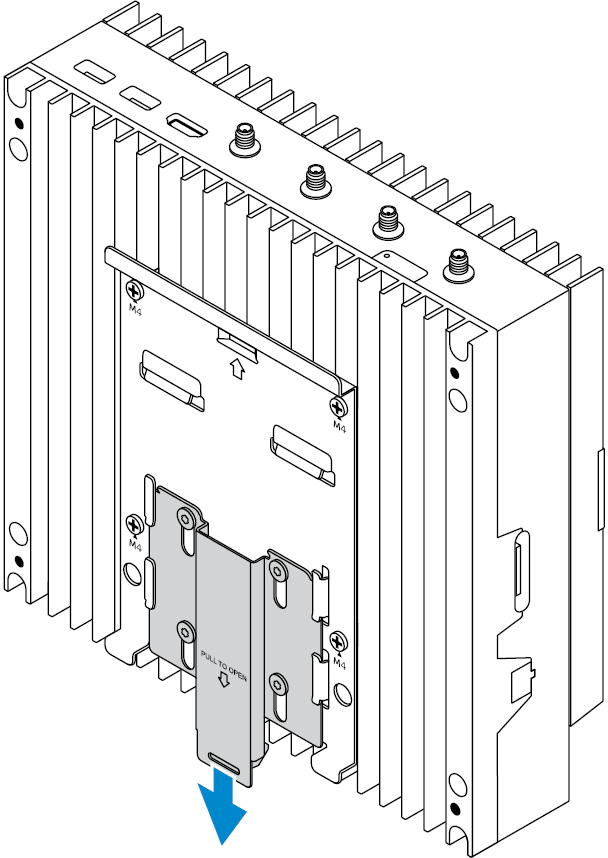

- Pull the tab on the bottom down to release the latch on the top-hat rail bracket (see picture 1).

- Remove the IPC from the DIN rail and present it to the technician.

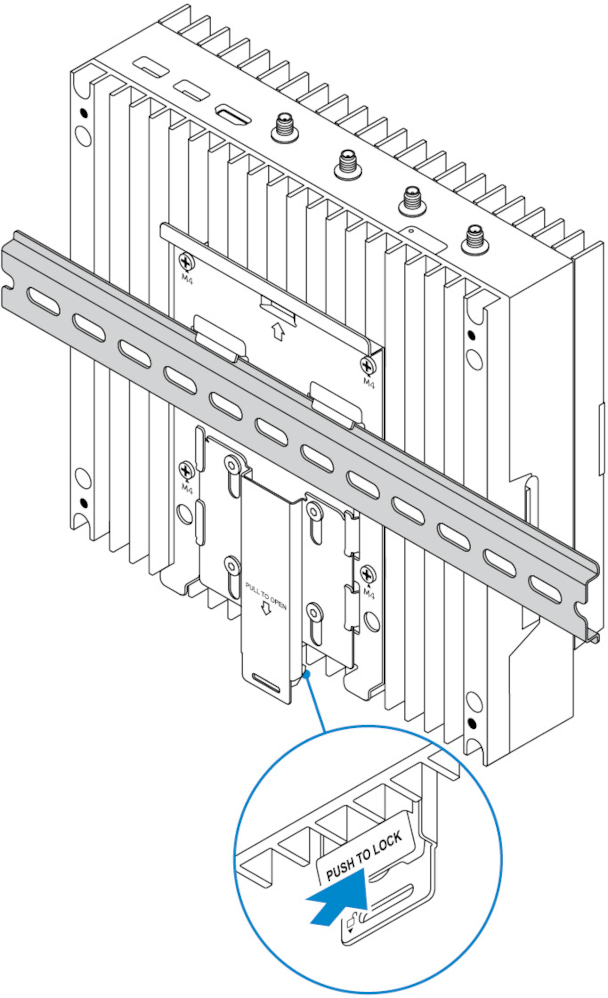

- After the service call, place the IPC back on the rail and secure it by pressing the latch (see picture 2).

- Reconnect the earth, network cable and power supply.

- Start up the IPC again.

- How can the network settings be reset (Edge Gateway)?

-

If the network settings have been changed so that C-Gate can no longer be reached via the network, you can reach it via a second emergency IP address.

- Connect directly by cable to the IPC on port 1.

- Read off the corresponding MAC address or emergency IP address on the housing.

- The emergency IP address is 169.254.0.0/16 in the network.

-

The MAC address 11:22:33:aa:bb:cc results in the emergency IP address 169.254.187.204.

- The first two blocks 169,254 are always the same.

- The last two blocks are derived from the last two blocks of the MAC address. Convert the numbers from hexadecimal to decimal representation.

- Configure your own terminal to be on the same network.

- Now you can reach the web interface via the IP address of the IPC with a browser and configure it correctly again.

- Why does no process data (e.g. voltage or current) appear on the dashboard?

Process data can only be displayed if you either have a Carola programme with the old list concept or you are working with the new QTI list concept and the control software version is QS2.8 or newer.

- Why are my components not being recorded correctly?

Compare the procedures from your MASTER programme with the documentation and adapt it accordingly. Be sure to use the procedures

SEAMSTRTandSEAMENDif you are using the module C-Gate.QM.- How is overall equipment effectiveness (OEE) or QINEO productivity calculated?

Overall Equipment Effectiveness (OEE) is composed of the metrics availability, performance and quality. QINEO productivity consists of the metrics availability and performance. The exact calculation can be found in the corresponding documentation.

- Why is the overall equipment effectiveness (OEE) or QINEO productivity low?

The metric availability depends on the capacity planning, which corresponds to the planned working time. For example, as soon as the plant or equipment is switched off, the plant is assessed as unavailable. For the performance metric, it is important that your component programmes are equipped with the documented Carola instructions and that the target times have been entered appropriately in the component templates. The quality metric is determined either automatically, via the process data, or manually, via an entry by the worker at the machine. QS2.8 or newer, QTI and SD monitoring and the module C-Gate.QM are required for automatic determination.

- Why does incorrect time information appear on the dashboard or in the component log?

The C-Gate time can be set in the settings of the web interface. Synchronise the time either manually or enter a time server for automatic synchronisation.

- Why are functions not licensed?

The functions of C-Gate are divided into modules, each of which must be licensed. Contact CLOOS for the licensing of further modules or installations.

- Why can't the robot exchange programmes with C-Gate?

The C-Gate programme management can only be used if the C-Gate.PG module is licensed for the corresponding robot and the robot has the 'Programme management with C-Gate' option set. In addition, either the C-Gate IoT Connector address (if available) or the C-Gate IoT Hub address must be stored in the robot. Furthermore, the robot's device-specific token must be stored in the robot settings. The robot must have at least software version QS2.12. From time to time it helps if the address of the C-Gate IoT Connector in the robot is set as the default gateway in the network configuration.