About C-Gate

Our modules

C-Gate consists of several software modules that you can activate depending on your individual digitalisation strategy. Modules are available after purchase on the C-Gate IoT Hub available after purchase.

Base

Skills

- Quick and easy network integration of your welding system for process data

Base

- Improvement of processes through measurable production output

- Vulnerabilities successfully identified in over 300 systems

Production

- Immediate reaction to deviations in the production process

- Automated quality verification of your components

- Fulfilment of the technical welding quality requirements

Quality

- No data loss and faster availability of your programmes

- Time reduction in case of programme change

- Traceability of all programme changes

Programmes

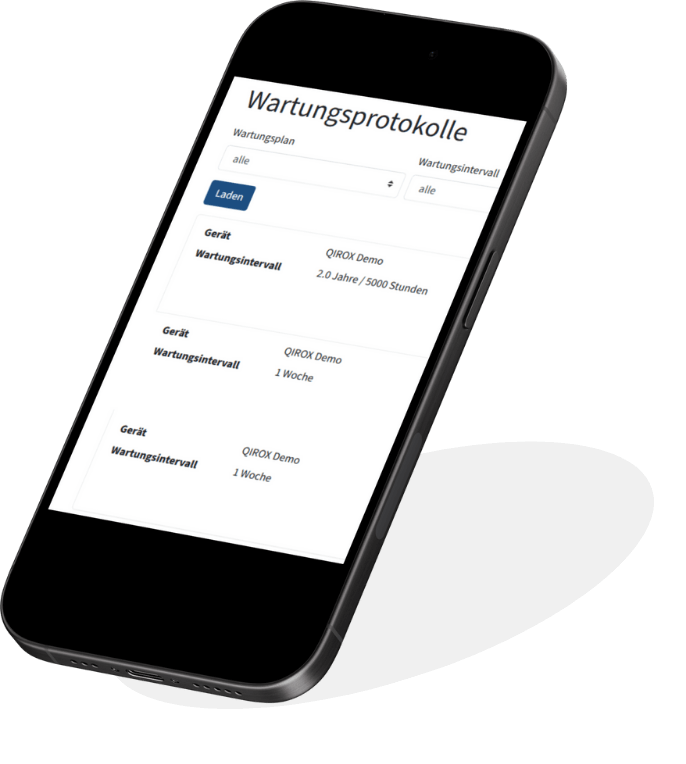

- Less downtime due to scheduled maintenance

- Required for ISO certification

- Predictive Maintenance

Maintenance

The Ultimate Suite includes all modules currently available.

Become a user now!Bernhard RothkegelProgrammer at Viessmann Berlin With the new C-Gate, we can network our robot systems and improve our production processes. In doing so, we primarily look at the overall equipment effectiveness (OEE) with the factors availability, performance and quality as well as the component-related key figures.