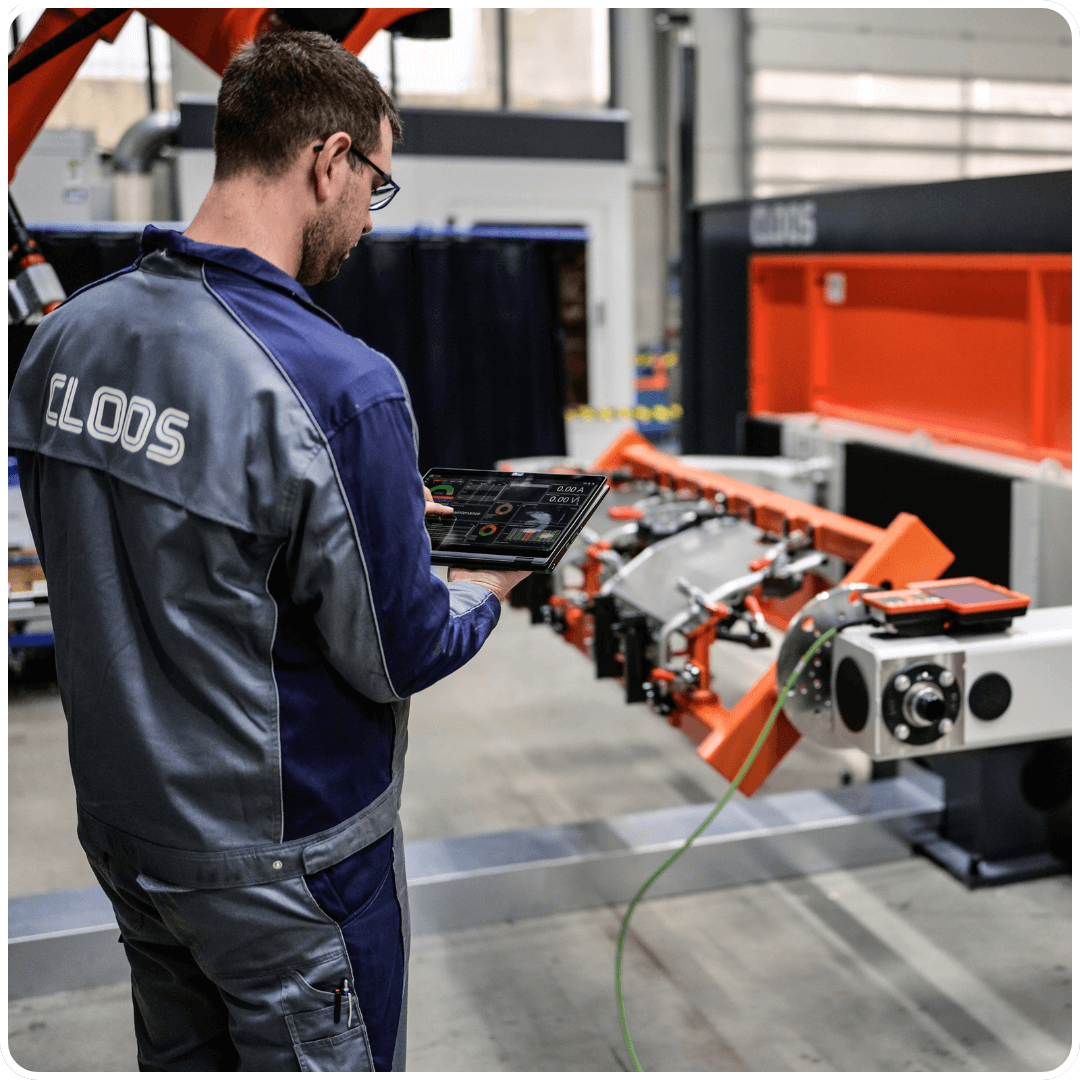

C-Gate IoT Platform

The digitalisation platform for your company!

at C-Gate

Access all relevant information about your welding production in real time in order to recognise weak points at an early stage and control production processes with foresight. Through continuous further development in close cooperation with our customers, we do everything we can to support you on the way to networked production.

Become a user now!Tobias NebenProgrammer at Viessmann Berlin C-Gate has helped to reduce waste because we understand the welding system better and have delved deeper into the welding process.

Advantages of C-Gate

20%

Increased efficiency

15%

Quality improvement

10%

Less downtime

Read reference reportChristian Kiechle, AGCO C-Gate helped us to analyse and optimise our welding system and the process in Hohenmölsen.